Ensun-U Pipe Solar Collector

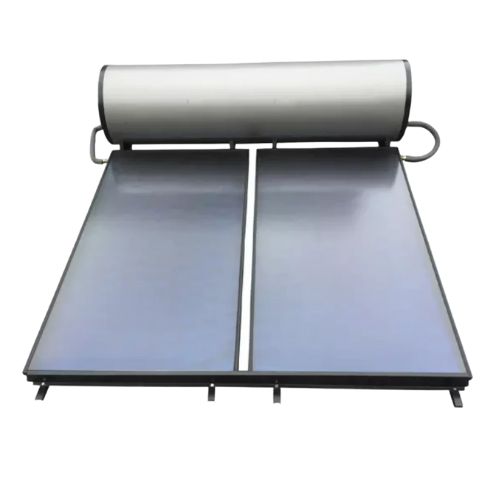

Ensun U pipe solar collector is a solar energy collector appropriate for the central hot water system. It is designed to absorb solar energy and to reach the principle of heating water.

- Lower maintenance cost

- Low-temperature resistance under -50℃ ambient

- Offers higher efficiency: 0.79 (aperture area)

- Tube can be replaceable without draining solar fluid

- Easy to install and maintain

- Available in 8 up 20 tubes model

- Can be combined with existing water devices

Professional U pipe Solar Collector Manufacturer in China

Ensun U Pipe solar collectors are the latest energy-saving product. It is made with the help of steel materials for connections, leaking phenomenon, and non-silicone aging to work strongly even if used for a long period of time.

Our solar collector is approved and certified by ISO 9001, SGS, CE, RoHS, and other certifications. Meaning you can get a quality and affordable price.

If you need U-pipe solar collectors. Don’t forget to message us now!

Wide Range of Applications

Our u pipe water collector are design to meet the demand application for:

- Domestic water heating. Our solar collector can be used in shower, kitchen, washing and more.

- Old heating equipment/system retrofit

- Room heating including radiator heating and under floor

- Large-scale commercial water heating system. It is used for hotels, school, hospitals, apartments and so on.

Our solar collectors are made with the following components:

- Manifold casing

- Inlet

- Insulation layer

- Header pipe

- Sensor port

- Vacuum tubes

- Outlet

- Frame

- U pipe

- Heat transfer Fin

- Tube cap and more.

Related Product

U Pipe Solar Collector

The U pipe solar collector constitutes multiple parallel tubes organized in U-shape used to convert the sun’s energy for heating purposes. Usually, these tubes are made from metals such as copper with high thermal conductivity.

To enhance solar absorption, the collector is often installed on a roof or a frame with the tubes towards the sun. The fluid flows naturally thanks to the collector’s U shape without the use of pumps or additional energy creating a thermosiphon.

Advantages of U Pipe Solar Collectors

U pipe solar collectors are a preferred option for solar thermal applications due to their many benefits some of which are highlighted below:

Cost-Effective

Compared to other solar collectors these have straightforward design with fewer parts making them more affordable. Their lack of supplementary pumping systems makes their installation and maintenance costs lower and thus a decent investment.

Durability

U pipe collectors are often constructed of durable and corrosion-resistant metals like copper. This guarantees performance in the face of adverse conditions enabling dependable performance that is long-lasting.

Efficient Heat Transfer

The wide surface area of these solar collectors effectively accommodates heat transfer when exposed to solar radiation. The collector heats up uniformly along its length thanks to the U-shaped design, maximizing the absorption of energy by the fluid.

Environmentally Friendly

Since they use solar energy that is renewable, U pipe solar collectors minimize reliance on fossil fuels. As such, they help create a more eco-friendly and clean environment by lowering carbon footprint and greenhouse gas emissions.

Options for Freeze Protection

To avoid ineffectiveness in colder climates, U pipe collectors can include freeze protection features. Such mitigation can include adding anti-freeze to the working fluid or adopting a drain-back system that drains the fluid when unused.

Natural Circulation

U pipe collectors work without requiring extra pumps infrastructure or energy input instead utilizing thermos phoning. The heated fluid continuously flows within the U-shaped construction simplifying the process and demanding less maintenance.

Scalability

It is possible to customize the heating demands of your U pipe solar collectors by scaling up or down. The system’s overall capacity can be increased by adding more collectors making it more flexible to meet different needs.

Versatile

These solar collectors can be put into a wide range of uses and are adaptable for both domestic and commercial application. They can be used for industrial processes needing moderate-temperature heat as well as domestic heating needs.

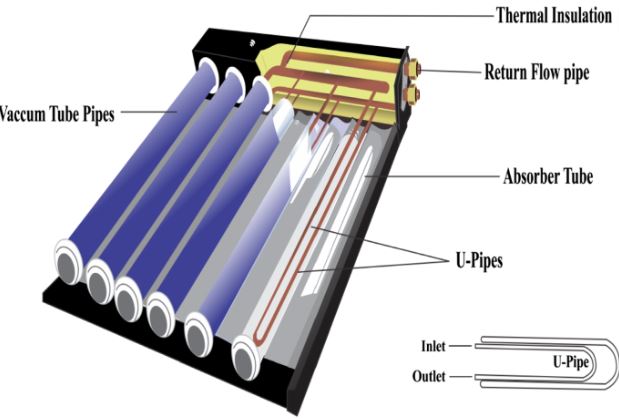

Key Components of the U Pipe Solar Collector

The components of U-pipe solar collector effectively absorb solar energy before transferring the energy to a fluid in form of heat. The heat is then supplied for various heating applications with the effectiveness and performance influenced by the component design and quality.

Collector Absorber

Their design is such that they absorb optimal solar energy. Usually, they have significant sunlight energy absorption capability.

Copper or aluminum are commonly used and maximum surface exposure is necessary to achieve increased solar absorption.

U-Shaped Tubes

Constitute the collector’s primary structure with U-shaped copper tubes or other high thermally conductivity material. The U-shape facilitates effective heat transfer and the fluid’s natural circulation with connection to inlet and output pipes.

Heat Transfer Fluid

This fluid, usually water or water-glycol combination, transfers captured heat from the collector to the area of application. In order to absorb the heat, the fluid moves through the U-shaped tubes initiating direct contact with the absorber plate.

Insulation

To reduce heat escape to the surrounding, insulation is crucial in a U-pipe solar collector utilizing insulating materials like foam or fiberglass. The absorber plate and collector are insulated improving overall collector efficiency and helping maintain temperature of the heat transfer fluid.

Glazing

It is the transparent cover shielding the absorber plate and tubes and allowing passage of solar radiation. Usually, tempered glass or clear plastic is used as glazing material which also offers protection against the elements. Glazing also aids in lowering heat loss through convection and radiation.

Frame

The frame gives the U pipe solar collector structural support and stability built of tough materials like galvanized steel or aluminum. The frame makes installation of the collector on a roof or other mounting structure easier safely securing the assembly.

Inlet and Outlet Pipes

These pipes allow for the flow of heat transfer fluid in the collector and are attached to the U-shaped tubes. These pipelines enable the flow of fluid into the collector, where it is heated by the absorber plate before transfer.

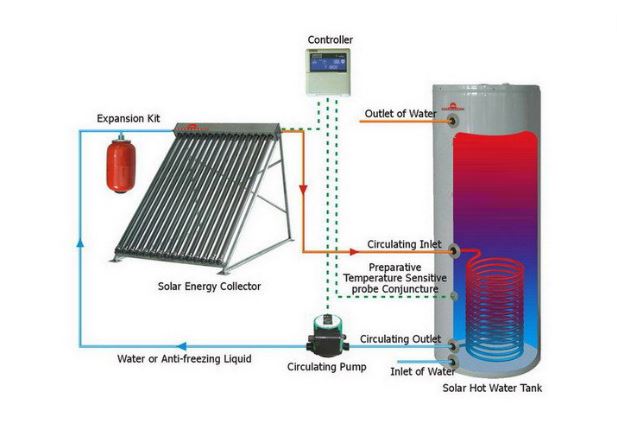

Working Principle of the U Pipe Solar Collector

U pipe solar collectors use natural convection for circulation and don’t need pumps or external energy sources. They are thus economical and energy-efficient for solar thermal applications because of their simplicity.

The basic idea behind a U-pipe solar collector is the gradual transformation of solar radiation into usable heat summarized thus:

Absorption of Solar Energy

This collector is made to absorb as much solar energy as possible by placing the collector with its back towards the sun. Material with high sunlight absorption capabilities is used for the collector’s surface converting absorbed sunlight into heat.

Heat Absorption

The collector’s heated surface is in direct contact with the heat transfer fluid flowing through the tubes. The heat transfer fluid is usually water or a mixture of water with glycol and captures absorbed heat via thermal conduction. The fluid’s temperature is raised by the heat, making it capable of carrying thermal energy.

Natural Circulation

The collector’s U-shaped design is essential to the operating concept allowing the heated fluid to rise thanks to thermosiphon action. It gathers buoyancy as it rises moving to the collector’s top where it makes a U-turn beginning descent via the opposite leg. The natural circulation caused by the temperature differential initiates the change in direction.

Return to the Collector

Remember, the downward flow results in a loss of heat to the surroundings. The cooled fluid is directed back to the collector’s base, where the cycle is repeated. Continuously moving through the collector, the fluid picks up heat, rises, turns around, and releases it.

Heat Transfer

Now, the heated fluid is thereafter sent to a heat exchanger or storage tank, where it is transported to the intended application. Domestic water heating systems employ the fluid in heating applications such as water heating and space heating.

Design Specifications

Depending on the particular application and requirements, a U pipe solar collector’s design requirement can change. Here are some typical design requirements to take into account:

Material for the Absorber Plate

Typically, a material with high heat conductivity and superior solar absorption capabilities is used for the absorber plate. Aluminum and copper find common use because of how well they conduct heat.

Frame

To give structural support and endure environmental factors, the collector requires a robust frame. The frame should be corrosion-resistant and capable of supporting the weight of the collection components, such as aluminum or galvanized steel.

Freeze Protection

Need to protect the collector from harm in cold climates warranties use of freeze protection procedures. A drain-back system drains the fluid from the collector when not in use, while insulation is also helpful. Using an anti-freeze solution in the heat transfer fluid also works.

Glazing Material

Glazing material should be transparent material to minimize heat loss while permitting solar radiation to flow through. Glass or tough polymers like polycarbonate are frequently employed as glazing materials.

The Inlet and Outlet Connections

These should be simple and secure for easy attachment of the heat transfer fluid pipes. In order to avoid leakage and guarantee effective fluid flow, proper sealing and connection techniques should be used.

Thermal Efficiency

Depends on the absorber plate’s design, glazing, the collector’s internal flow dynamics and insulation. To enhance heat absorption and minimize heat losses, the design should be optimized.

Tube Diameter

The system’s flow rate and heat transfer properties are influenced by the diameter of the tubes. Considerations like pressure drop, heat transfer needs, and desired flow rate should all be taken into account when choosing the tube diameter.

Tube Length and Configuration

The application needs, available space and collector size influence the length of the tubes. The tubes’ arrangement and number of U-shaped bends is crucial in optimizing the surface area available for heat transfer and natural circulation.

Tube Material

For efficient heat transmission, the U-shaped tubes carrying heat transfer fluid should have exceptional thermal conductivity. The outstanding thermal conductivity, resistance to corrosion, and durability of copper make it a popular choice.

Improving Performance of a U Pipe Solar Collector

Several techniques can be used to increase a U pipe solar collector’s effectiveness and performance. Here are some suggestions:

i. Enhance Absorber Plate Coating: The effectiveness of the absorber plate can be increased by coating it selectively with a material with low emissivity and high solar absorptivity. Selective coatings minimize heat loss through radiation while absorbing a larger amount of the solar spectrum.

ii. Enhance Insulation: Effective insulation can reduce heat losses to the environment along the sides of the collector and the rear of the absorber plate. More heat is held within the collector thanks to improved insulation, which lowers heat conduction and convection.

iii. Use Reflectors: These help in directing more sunlight to the absorber plate utilizing reflective objects, like films or mirrors positioned purposefully around the collector. The amount of solar energy captured is increased by this strategy of reflector optimization.

iv. Enhance Glazing Properties: Glazing with low heat conductivity and high solar radiation transparency can reduce heat loss. Transmission of solar radiation into the collector also improves by utilizing anti-reflective coatings or low-iron glass.

v. Increasing the Absorber Plate’s Surface Area: This increases the amount of solar radiation that is absorbed and transformed into heat. This can be done by implementing a design with multiple absorber plates or by expanding the collector’s size.

vi. Optimize Properties of Heat Transfer Fluid: Heat transfer fluid efficiency can be improved by using a fluid with low viscosity and high specific heat capacity. Additionally, it is possible to optimize heat exchange within the collector by using a fluid with optimal flow rate.

vii. Installation and Placement: The collector’s performance depends on how well it is installed and positioned. Achieve maximum solar exposure and thus energy absorption by positioning the collector along the sun’s path, tilting it at an ideal angle.

viii. Improve Tube Design: This improves heat transfer and natural circulation via improved flow dynamics and heat transmission within the collector. Factors including the diameter and length of the tubes, as well as the bend count and configuration are responsible.

ix. Regular Maintenance: Includes cleaning the glazing and absorber plate on a regular basis, checking the system for leakages or broken parts. These efforts aid in preserving collector functionality ensuring optimum efficiency.

Application of U Pipe Solar Collectors

U pipe solar collectors can be used in a variety of contexts covering industrial, commercial, and residential needs. These collectors are frequently used for the following purposes:

Domestic Water Heating

When used for heating household water, U-pipe solar collectors use the heat transfer fluid to distribute absorbed heat. The heat warms up water in storage tanks or directly heat up water used for domestic needs like bathing and washing. This is helpful in dependency on conventional energy sources thus reducing utility costs.

Hybrid Systems

U pipe solar collectors are compatible with hybrid systems utilizing alternative energy sources like traditional boilers or heat pumps. The solar collectors contribute a sizeable amount of the heat demand, resulting in the best possible energy utilization. This guarantees heat supply even during times of insufficient solar radiation.

Industrial Processes

U pipe solar collectors can be utilized for a variety of industrial operations with moderate heat requirements. For instance, they can supply thermal energy for preheating, drying and sterilizing in textile production, agricultural and food processing.

Pool Heating

U pipe solar collectors can directly heat pools disregarding need for gas or electric heaters. Heat is transferred to the pool water through a heat exchanger by the heated working fluid allowing all season pool use.

Space Heating

The viability of U pipe solar collectors for space heating is undisputed with collected heat supplied to a heat exchanger. The exchanger heats up the air for air conditioning or channeled into a hydronic system useful in heating interior spaces. Utilizing this kind of space heating is a cost effective as well as energy efficient alternative to conventional heating systems.

Conclusion

U pipe solar collectors are a desirable option for harvesting solar energy for heating because they provide effective heat transfer. This affords users many advantages like energy and cost savings in the long term with the added benefit of being environmental friendly.

More Resources:

Solar Water Heaters – Source: Energy

Solar Water Heating System – Source: Science Dircet