Ensun-Pre-Heated Solar Water Heater

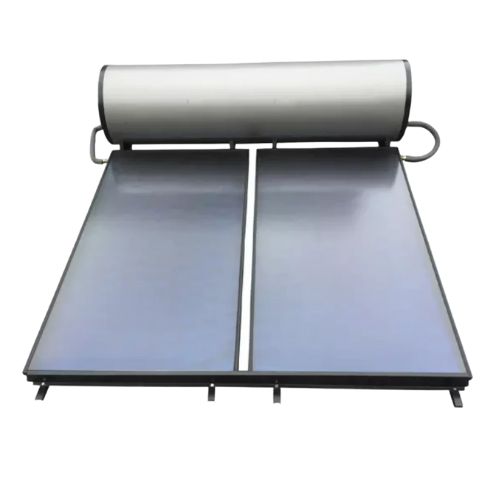

Ensun Pre-heated solar water heaters are also known as solar domestic hot water systems. It is an effective way to generate hot water for your home or in any other place.

- The water can be heated rapidly

- Offers complete automatic operations

- No risk for corrosion

- The hot water goes out with high pressure

- High wind load strength

- High snow load strength

- No risk for scale deposit

Your Leading Pre-Heated Solar Water Heater Manufacturer

Ensun pre-heated solar water heaters are designed to reduce your hot water cost by up to 65 to 75%. You can assure that this is easy to install due it comes with complete components.

Our solar water heaters are manufactured with the use of special insulated stainless steel solar piping and also fitting. We can provide you OEM and ODM service together with quality assurance, aftersales service, and affordable prices.

If your need a solar water heater, Don’t forget to message us now!

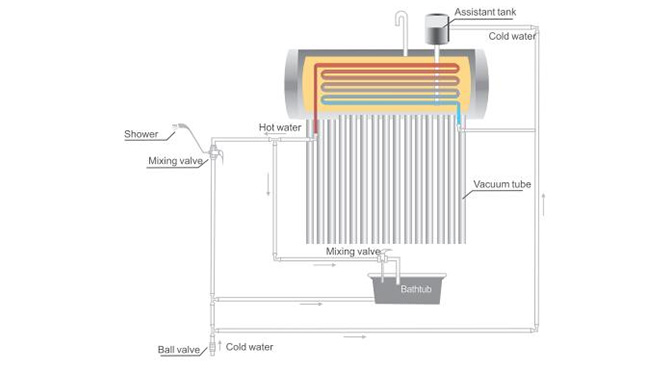

Pre-Heated Pressurized Solar Water heater is similar to compact non pressure solar water heater, but designed with a coil heat exchange inside of water tank. Because the coil can withstand the pressure of city water, it can be recoganized as pressure solar water heater too. Normally the hot water inside of water tank is only for heat storage. People will use the water inside of coil. It is fresh and pressurized warm water. It can be used for room heating too if you install several pieces of solar water heater in series and then connect it to floor heating pipe.

Type of Solar Water Heating System

Our pre-heated solar water heater are available in different types such as:

-

- Pre-heat solar tank system. This solar heating use two tanks wherein the first tank is known as a solar pre-heat tank. The 2nd is a basic solar hot water storage tank that has an internal heat exchanger

- Solar Combo System. It is a combination of the solar pre-heat tank with an electric backup a heater in a single unit.

- Solar with tank-less. It is the process where the water is pre-heated into the solar storage tank before it goes into the tank-less heater.

KESUN Flexible Pipe is Fixed with Plastic Support

The stainless steel flexible pipe are fixed on a plastic frame tightly. And then whole group will be put inside of water tank. The coil will be average located inside of water tank well. There is no need welding to fix the coil into tank.

Other Company Flexible Pipe is Fixed by Welding

In some other factories, they tie up the coil on a stainless steel bar. And then weld the bar to inner tank. It is big risk to damage the inner tank. And the coil will move inside of tank when the pressure water pass through the coil.

Kesun Coil Direction

It is horizontal direction of Kesun coil. The cold water inside of coil is heated from bottom circle to up circle gradually. As you know the hot water are aways on top. So the hot water will come out from top circle finally.

Other Company Coil Direction

Due to the fixing way, they can design the coil circle around the fixing bar only. When it works, the water inside of pipe will bring the heat energy of hot water from top of water tank to down part, it is not a good heat exchange way.

When buying and installing a solar water heater you should consider the following below:

- Determine the correct size

- Investigate covenants, local codes, and regulations

- You need to evaluate your sites and solar resource

- Then estimate the cost and energy efficiency

Related Product

How It Works

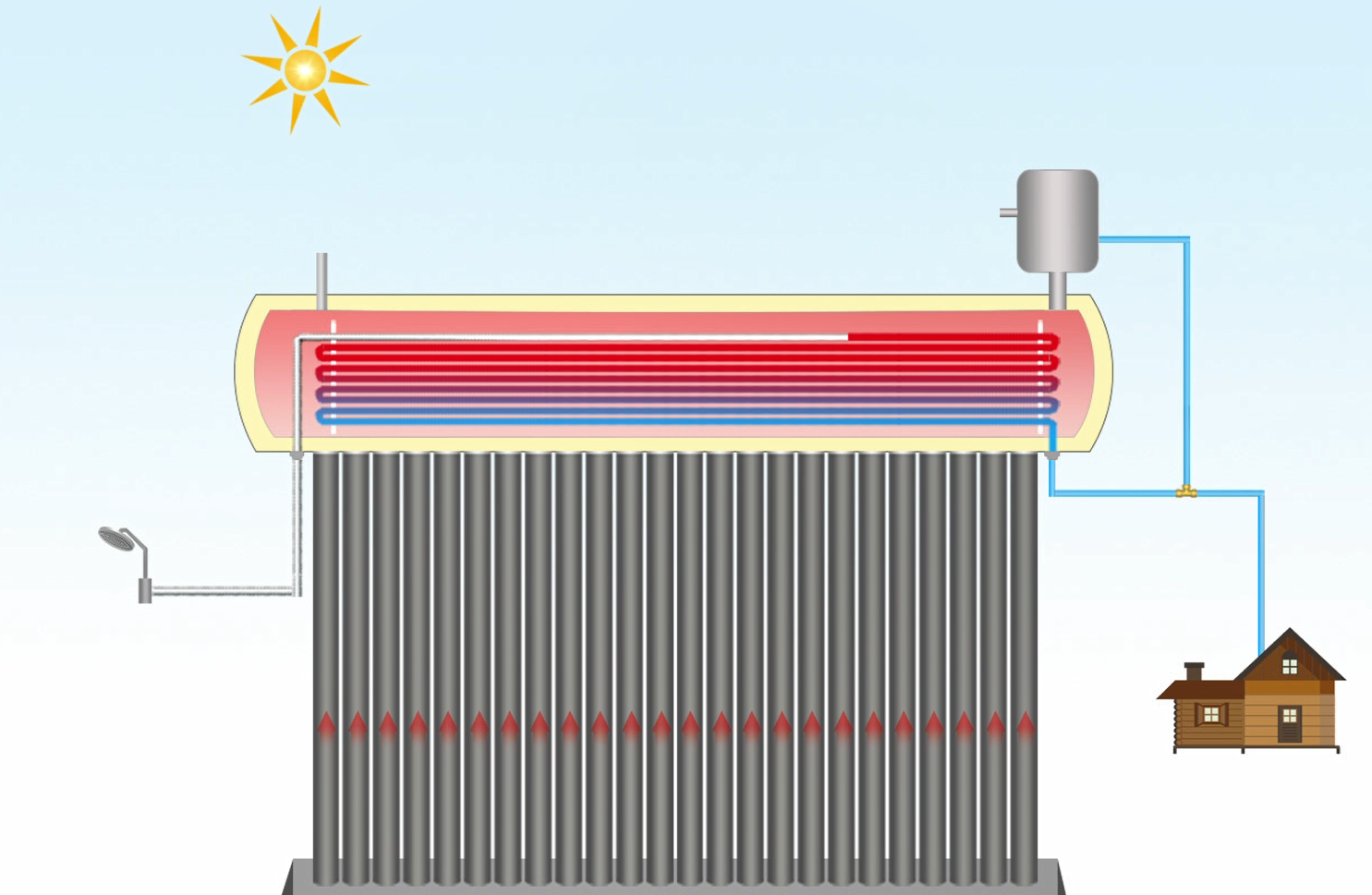

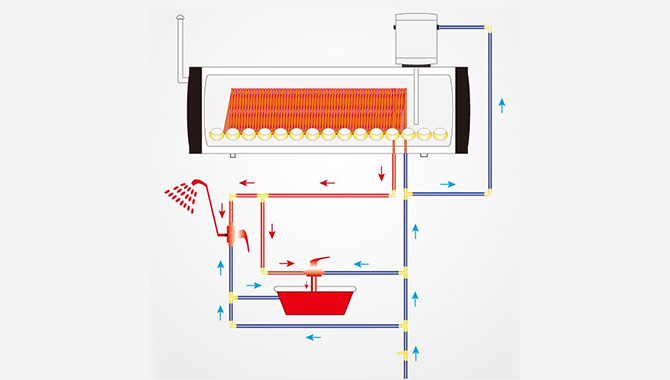

Pre-heated solar water heater operates in the manner described below in order.

- The solar glass tube transforms sunlight radiation into thermal energy after absorption.

- A thermosiphon is the reversal process of water. Tanks receive the hot water from the tube. And cold water from the tank goes into tubes.

- Coldwater that goes to the copper coil inlet is heated. It’s where the inner tank contains its hot water.

- And that’s it; hot water is ready.

Beneficial Characteristics

Ensuring the best performance for using a pre-heated solar water heater relies on its excellent characteristics. Here are among them.

- The pre-heat system of this solar water heater is capable of instant supply. It can provide hot water without taking a long time to heat.

- Even in cold or low-temperature environments, it offers good heating efficiency. Since the tank is heated, it won’t freeze.

- In terms of holding water, the system is more capable. That is because the tube, where circulation happens, contains water. Therefore, the system can hold roughly 400 liters of water at a 300L tank capacity.

Various Components

Here are the following components of pre-heated solar. The main and the optional, if required.

Main

| Components | Specification | |

| Evacuated Tubes | Dimension | Length: 1.8m |

| Inner: 47mm | ||

| Outer: 58mm | ||

| Thickness: 1.65mm | ||

| Solar Absorber Coating | Emittance (80 C) | <8% |

| Heat loss

(m2 C) |

0.8W | |

| Water Tank | Temperature | Startup: 0°C |

| Operational: 55-95°C | ||

| Mounting Frame | Material | Stainless Steel, Aluminum alloy, Galvanised Steel |

| Rubber Components | Material | HTV Silicone |

Optional

| Components | Dimensions | |

| Assistant tank | Capacity: 5L to 20L | Size: ¾ inch |

| Magnesium rod | Length: 22mm x 300mm length | |

| Electric heater | Connection size: 1-inch | Power:1500 to 2500 watts |

| Thermostat | Connection size: 1.25-inch | |

| Luxury controller | Quantity:1 unit | Voltage:110v to 220V |

| Economic controller | ||

Corrosion Resistant of Coil

KESUN AISI 316 stainless steel surface with special treatment

Without any corrosion after salt spray test.

Test facility:

Salty spray testing machine

Test condition:

– 240 hours continuous test

-Spray pressure 1.5bar

– Room Temp. 35℃±1℃

– Pressure can temp. 47℃±1℃

– Humity 85% up

– Solution PH value 6.5~7.2

– NaCl analytical pure

– Solution concentration 5%

– Spray amount 1.0~2.0 ml/80cm2/H

– Tested quantity 10 pcs

Copper

Electrical corrosion

Electrical corrosion happen is due to the electrochemical reaction between two different metal material. Both stainless steel inner tank and copper pipe are corrosion resistant material. But it will rusted when you put them together. That is why we change to use flexible stainless steel coil instead of copper coil.

Other AISI 316 stainless steel

Rust spot happen after 72 hours

Test facility:

Salty spray testing machine

Test condition:

– 72 hours continuous test

-Spray pressure 1.5bar

– Room Temp. 35℃±1℃

– Pressure can temp. 47℃±1℃

– Humity 85% up

– Solution PH value 6.5~7.2

– NaCl analytical pure

– Solution concentration 5%

– Spray amount 1.0~2.0 ml/80cm2/H

– Tested quantity 3 pcs