Ensun-Flat Plate Solar Collector

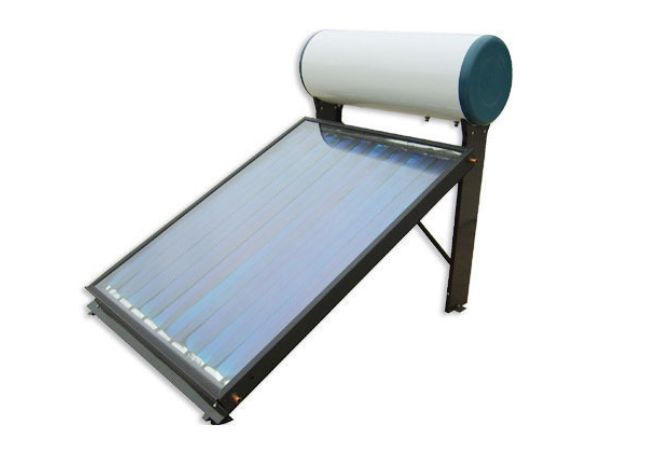

Ensun flat plate solar collectors are devices that use solar energy just to generate thermal energy. These are the device that has the economical cost of investment.

- Easy to install and maintain

- No tracking equipment is required

- Provide high energy even in a low temperatures

- Clean and pollution-free

- The power is natural and renewable

- Provide longer service life

- Low cost

Your Reliable Flat Plate Solar Collector Manufacturer in China

Ensun flat plate solar collectors are capable to deliver the necessary quantity of hot water depending on your required temperatures. These are consist of large sheet of copper as a conductor of heat which chemically etched back to absorb solar radiation for maximum efficiency.

As a provider, we assure to provide you with quality and affordable prices for solar collectors just to meet your needs. Ensun offer customize service, quality assurance, fast delivery, and aftersales service. You can assure that you will get our flat plate collectors at the time you wanted.

Feel free to message us now!

Application of Flat Plate Solar Collector

Our flat plate solar collectors are designed to capture solar energy that use for the following applications:

- Home for bathing

- Washing and heating

- Heat outdoor swimming pool

- Hot tubs

- Showers

- And other hot water applications

We manufacture flat plate solar collectors that equipped with different main components such as:

- Glazing cover. A transparent layer that use to transmit radiation to absorber

- Black surface. Absorbent of incident solar energy

- Support structures. Design to protect the components and hold them in proper places

- Insulation cover. To reduce heat loses

- Contains heat fluid to transfer heat from collectors

- And more

Related Product

Flat Plate Solar Collector – The Ultimate Guide

A flat plate solar collector refers to a uniquely constructed solar collector system that uses a conductive metal inform of a plate.

To improve its ability to absorb solar radiation and maximize the effectiveness of the collector, the plate is chemically etched or black.

The surface constitutes copper pipes running in parallel across its length known as risers. These pipes conduct the working fluid in the system which many a times is just water making circulation possible.

How Flat Plate Solar Collector Works

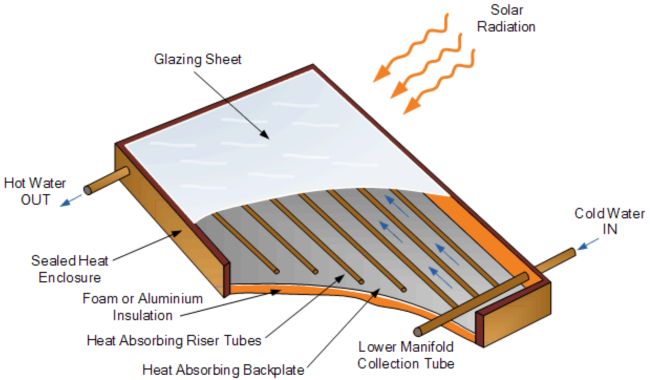

Absorption of Sunlight

Sunlight enters the flat plate solar collector via the transparent cover built to maximize solar radiation transfer while minimizing heat loss. The darkened copper or aluminium absorber plate is usually below the transparent casing. Darkening the surface ensures the absorption of more solar radiation and as such the resulting converted heat energy.

Heat Transfer

The late transforms sun radiation into heat energy. Consequently, this heat is transferred to the working fluid.

In most solar water heater designs of this nature, the transfer fluid is mostly water.

For more heat transfer, the pipe network carrying the heat transfer fluid is kept very close to the absorber plate.

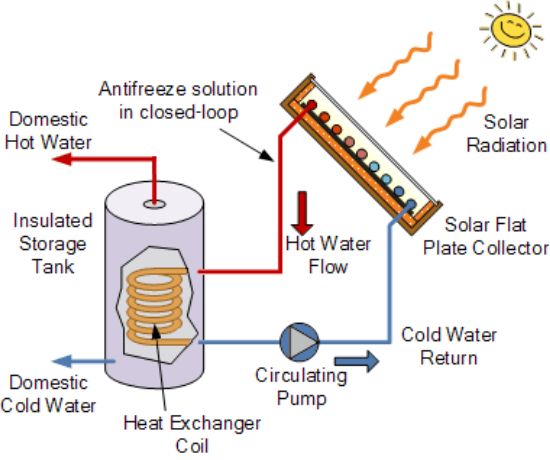

Heat Transfer Fluid Circulation

Usually, the heat transfer fluid will absorb heat from the flat plate to the water heating system.

Where water is employed as working fluid, it can be utilized directly and stored in a tank. Sometimes when used for other purposes other than water heating, it can be distributed to an exchanger.

Preventing Heat Loss

Preventing heat loss is critical in the working process of these heat collectors systems since it is one of the principles of efficiency. Insulation lowers the rate of heat loss to the environment allowing the collector to retain most of the harvested energy.

On the backing sides of these heat collector systems, you will find either foam or fiberglass insulation material.

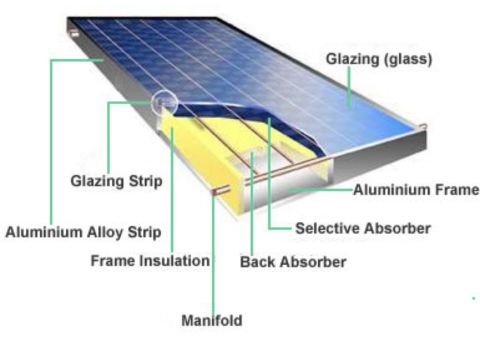

Flat Plate Solar Collector Components

Components work mutually in the capturing of solar energy, its transformation into heat, and transmission to a working fluid for application use. When examining a flat plate solar collector, you will identify these compponents:

Transparent Cover

It is located above the absorber plate, working to minimize heat loss while permitting sunlight passage. The transparent cover traps solar radiation producing a greenhouse effect useful in keeping heat inside. Materials with good optical qualities like glass or plastic are used to make the transparent cover.

Absorber Plate

The absorber plate is basically plate like construction capable of conducting heat. It is fashioned form good heat conducting materials like copper and aluminium. As the sun reaches the absorber plate, its temperature will begin to increase.

Usually, the piping network for conducting the working fluid is directly attached to the absorber are to increase absorption efficiency. The temperature increase observed in the absorber plate is transferred to the working fluid which then flows conventionally.

Insulation

The flat plate solar collector’s sides and back are insulated to reduce heat loss and improve efficiency. When you employ insulation like fiberglass and/or foam, you reduce the amount of heat lost to the environment. Insulation helps optimize the quantity of solar energy taken in by limiting external escape of heat.

Heat Transfer Fluid

The fluid heat transfer fluid helps in transferring the useful heat energy to the intended area for heating process.

Water finds common use as the heat transfer fluid especially for domestic collectors.

Other specialist heat transfer fluids like water-glycol combinations, are used when the heat is utilized for other use like space heating. The working fluid is contained and transported within a pipe network of highly conductive material and close to the absorber plate surface.

Casing and Frame

A strong casing or frame offering protection and structural support encloses the flat plate collector’s components. Typically, steel or aluminum are used to make the casing which helps maintain appropriate component alignment and preserves collector integrity.

Manifold and Piping

The heat transfer fluid’s input and output pipes are connected by a distribution system called a manifold. It improves the circulation of the heat transfer fluid via the collector and guarantees correct flow distribution to the absorber plate. When implementing a heat exchanger or directly storing the heated water, you utilize a piping network.

in Flat Plate Solar Collectors

The common fluids utilized in these collectors are water and a solution combining it and antifreeze. The particular antifreeze solution to use is dependent on climate and the solar collector system’s intended use.

A common solution is a mixture of propylene glycol anti-freeze and water. It prevents freezing of the system in cold weather while still capable as a heat transfer medium for storage or distribution.

There are instances where using water alone as the heat transmission fluid is possible, especially in regions with warmer climatic conditions. This, however, reduces the system’s resistance to subfreezing temperatures.

The selection of heat transfer fluid depends on the system design, regional climate, and particular requirements. For the proper fluid selection for a flat plate solar collector system, always refer to the manufacturer’s instructions or a solar thermal specialist.

Flat Plate Solar Collector Types

For optimum effectiveness, proper dimensions, alignment, and maintenance are also essential. Expert advice is encouraged before making a choice on what collector type you should acquire.

Glazed Flat Plate Collectors

Glazed collectors are the most popular type with a translucent glass cover that minimizes heat loss while permitting light passage. With the dark coating on the covers, there will be an increase in solar energy absorption.

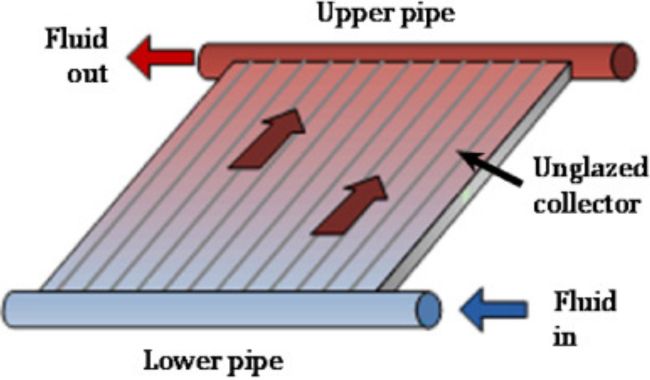

Unglazed Flat Plate Collectors

These have no transparent cover making their design more straightforward than glazed collectors with the absorber plate exposed to the sun directly. Applications like pool heating, which don’t demand higher temperatures commonly employ these type. They are the more affordable and effective choice in warmer climates.

Benefits of Flat Plate Solar Collectors

For the greatest potential for benefit, proper system design, sizing and installation are crucial.

When investing in solar thermal options, flat plate solar collectors are typically selected for their advantages as discussed below:

i. Cost-Effective: Compared to other alternative sources of heat energy, flat plate solar collectors are more affordable considering their energy savings in the long run. Compared to other solar collectors, they have a straightforward design with simple construction making installation easy.

ii. Efficiency: These panels absorb sunlight and ensure optimal heat energy transfer into the systems you want to heat.

iii. Reliability: The benefits of going with these collector over time are evident given their extended service life. There have been design improvement giving flat plate collectors a long lifespan of delivering dependable performance when installed and maintained correctly.

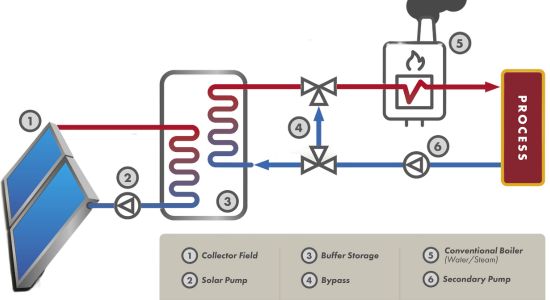

iv. Flexibility: These collectors can be utilized in instances requiring low-temperature heating such as water for domestic applications and pools. They can also be utilized as independent devices or integrated with conventional heating systems.

v. Environment Benefits: They use sun’s clean and renewable energy, decreasing the need for fossil fuels. Consequently, they help minimize carbon emissions, improve air quality, and have a smaller environmental impact.

vi. Low Maintenance: Flat plate collectors require very little maintenance, with tasks limited to regular absorber plate and cover inspection and cleaning. The lack of moving parts or intricate systems makes flat plate collectors less expensive to operate.

Flat Plate Solar Collector Applications

Many heating applications undertaken in residences, commercial developments and industrial processes can be achieved by utilizing these collectors.

a. Domestic Water Heating: The heated water is utilized for bathing, washing, and other domestic chores to which they are efficient and economical.

b. Space Heating: Houses, offices and other encloses living and working areas can utilize the solar collectors to heat their internal atmosphere. They give warmth and comfort to the indoor environment by heating air via the heat transfer fluid. This reduces dependency on traditional heating techniques allowing integration with forced-air heating systems or radiant floor heating systems.

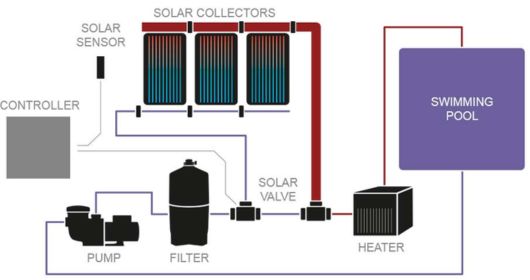

c. Pool Heating: These collectors when implemented in swimming pool plumbing systems can be used to warm inlet water. This is especially useful in extending swimming to colder seasons without high investment.

d. Industrial Process Heating: Utilizing solar energy allows businesses to operate more cheaply with less reliance on fossil fuels.

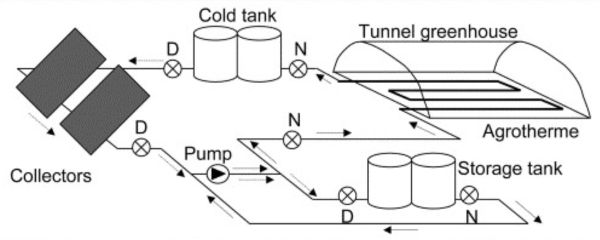

e. Applications in Agriculture: Flat plate solar collectors can be used to heat greenhouses, supplying the temperature required for ideal plant development. Additionally, agricultural items like grains, fruits and vegetables can be dried using solar thermal systems.

Limitations of a Flat Plate Solar Collector

Identifying limitations of an equipment before investing is a standard procedure which is no different with flat plate solar collectors. Some potential points of limitation are highlighted thus:

Heat Loss

Although flat plate collectors are designed to reduce heat loss, some thermal losses may still occur through conduction, convection, or radiation. Even though good installation methods and insulation can reduce these losses, some heat dispersion is unavoidable.

Efficiency Dependence on Weather

The amount of sunlight reaching your flat plate solar collector will be affected by the prevailing atmospheric conditions. Days that are cloudy or overcast can drastically reduce the quantity of solar energy available for collection, ultimately affecting performance and heat output. Their effectiveness may also be affected by seasonal changes and shadowing from surrounding structures or vegetation.

Freeze Protection

Sometimes temperatures can drop to freezing levels making flat plate solar collectors utilizing water in danger malfunctioning. If suitable safety measures aren’t taken, the fluid inside the collector and pipe system could freeze and cause damage. Drainback systems and antifreeze solutions can be useful in avoiding freezing, however at increasing cost and system complexity.

Higher Temperatures Limitation

While the effectiveness of flat plate solar collectors in generating enough heat to support heating application is undeniable. However, it is limited to low and medium heat applications. These primarily include heating internal air spaces and water. Achieving high temperatures needed for specific industrial processes or applications is not possible with theses collectors requiring other options like solar towers.

Initial Investment

They provide long-term cost saving. Cost typically includes system integration, plumbing and piping, as well as the purchase and installation of the collectors.

Maintenance Needs

Although flat plate collectors typically require little care, the collection surface requires cleaning regularly to remove dust, dirt, or other material. Accumulation of dirt lowers the collector efficiency with regard to the amount of solar radiation that reaches the absorption plate.

Space Requirement

The spatial requirements for flat plate solar collectors is significant especially where numerous collectors are required to satisfy the specified heat requirement. To maximize solar exposure, a suitable roof or ground area must be accessible and angled appropriately which is challenging in metropolitan settings.

Weight and Structural Considerations

Flat plate solar collectors, particularly those built onto rooftops, can increase the structure’s weight and thus affect integrity. Make sure the building’s structure can withstand the collector weight especially when installing over an existing structure not intended prior.

Factors Affecting Performance of a Flat Plate Solar Collector

Some of the factors that will influence collector performance are summarized below:

Absorber Plate Material

The composition and coating of the absorber plate have a major influence on the performance of the collector. High thermal conductive materials, like copper or aluminum, are typically employed. The dark coating improves heat absorption properties

Ambient Temperature

The ambient temperature affects how much heat is lost by the collector to its surrounding. Greater dissipation of heat is observed to be caused by warmer ambient temperatures.

Collector Area

Large surface solar collector implies more energy absorption.

However, the collector area, is affected by the available space, the required energy, and economic factors.

Collector Obstruction

Dirt, dust and other foreign material can build up on the collector surface of the collector obstructing sunlight and rendering it less effective. To maximize collector performance, routine cleaning and maintenance is necessary to remove dirt and keep a clean surface.

Flow Rate

That rate of flow of the heat transfer fluid will determine how much heat or thermal energy will be successfully transferred. A sufficient flow rate ensures effective heat transfer between the fluid and the absorber plate and helps maintain ideal temperature differentials.

Insulation and Glazing

The properties of the glazing will determine the ability of the collector to successfully retain heat. Clear plastic or glass covers permit sunlight while preventing heat loss. On the other hand, insulation, ensures there’s a greater temperature differential by reducing heat dissipation thereby enhancing overall performance.

Orientation and Tilt Angle

The tilt angle determined amount of solar absorption. Since the installation site’s elevation and the intended heat output differ, the tilt angle will be different from site to site.

Solar Radiation

More sunlight will definitely translate to higher heat energy output. Better collector performance is typically obtained in places with higher solar radiation levels, such as those around the equator.

Moreover, the amount of solar energy reaching the collector surface is influenced by cloud cover, seasonal fluctuations and shading by buildings or vegetation.

Heat Transfer Fluid

Water, sometimes in combination with antifreeze, is the most typical medium for heat transfer. When selecting the fluid, it is necessary to consider factors like thermal characteristics, freezing point and viscosity.

System Design and Control

The system’s overall design including how the collector is integrated with storage or distribution systems can impact performance of the collector. Also, the architecture of the pipework and the control mechanisms greatly influence effectiveness in heat transfer and losses.

Flat Plate Solar Collector Efficiency

The efficiency, usually represented as a percentage, should be taken into account while assessing the effectiveness of a solar collector.

When considering efficiency, it is vital to evaluate other factors like available space, and application needs. In assessing the collector efficiency of your flat plate collector, the following pointers are discoverable:

Thermal Efficiency

This describes the ratio between effective heat resulting from the harvested solar radiation and the total. It is arrived to by dividing the heat output by the received solar radiation. Different factors like collector design, operational conditions, materials utilized and efforts for insulation influence thermal efficiency.

Optical Efficiency

A flat plate collector’s optical efficiency dwells on the effectiveness of the collector in capturing solar energy. In describes the success in absorbing solar radiation in relation to the total amount of solar energy available. The optical efficiency is affected by variables such as glazing properties, coating, type of absorber material and angle of incidence.

Overall Efficiency

When examining the solar collector efficiency, you must analyze both the optical efficiency and thermal efficiency.

It takes into account the losses in terms of energy by transporting the heated fluid not limited to radiation, conduction, and convection.

Factors Affecting Collector Efficiency

Efficiency is affected by factors like collector orientation and tilt angle, radiation levels, absorber plate material and coating. Additionally, glazing qualities, fluid flow rate, insulation, and ambient temperature also influence how well the collector absorbs, converts and transfers heat energy.

Efficiency Variation

When using a flat plate solar collector, the efficiency will vary with the prevailing conditions of the environment it is applied. Higher radiation levels, appropriate collector orientation and tilt, and reduced dissipation, positively influence efficiency. Additionally, factors including collector contamination, coating deterioration over time, and maintenance procedures may have an impact on efficiency.

Flat Plate Solar Collector Installation

The installation process of a flat plate solar collector entails the appropriate integration of the equipment to your plumbing infrastructure. This process captures the activities form deciding where to install the collectors to making an operational run.

- Site Evaluation: Perform a complete site inspection before installation to ascertain the location’s suitability. Consider the available solar exposure, shading from surrounding buildings or trees, roof condition and orientation, and structural issues.

- Design and Sizing: Select the system’s size based on the energy required and available space. For maximum system performance, take into account the collector area, radiation levels, fluid flow rates and tilt angle.

- Mounting Structure: Install an appropriate mounting system to hold the collectors in place. Depending on the installation site (rooftop or ground) the mounting structure may vary. For roof installation, the structure should be capable of withstanding the collector(s) weight alongside environmental variables like winds.

- Collector Placement: Maximize solar exposure by properly orienting the flat plate collectors at the desired tilt angle on the mounting frame. Utilizing the proper mounting gear, fasten the collectors to the building to ensure a safe and level installation.

- Piping and Plumbing: Flat plate collectors should be connected to the building’s piping and plumbing system. This entails setting up pumps, valves, supply and return lines and even controllers. The amount of heat lost during fluid movement is reduced when proper pipe insulation is utilized.

- Insulation and Glazing: Install glazing material (plastic or glass) over the collector surface to prevent air or moisture infiltration by ensuring the seal is tight. For limiting heat loss, insulate the collector rear and sides with the proper insulating material.

- Heat Transfer Fluid: Adding the appropriate medium for heat transfer such as water allows you to transport the absorbed heat to application areas. To promote effective heat transfer, make sure the fluid levels are appropriate and remove air pockets.

- Integration with Storage or Distribution System: Depending on the application, attach the flat plate collector system to the distribution or storage system.

- Electrical Connections: Make the appropriate electrical connections and ensure correct grounding if the system incorporates pumps, controllers, or sensors. When wiring, adhere to safety regulations and electrical rules.

- Testing and Commissioning: After the installation is finished, thoroughly test the system to ensure its effectiveness before official use. This include inspecting for leaks, confirming fluid flow rates, determining temperature differences, and ensuring that controls are working properly.

Performance Specifications of Flat Plate Solar Collectors

To comprehend the precise performance traits of a given collector model, it is crucial to check manufacturer specifications and independent test reports.

The following are some important performance specifications to take into account when evaluating flat plate solar collectors:

i. Freeze Protection: In colder climates, freeze protection is particularly crucial describing how the collector system’s ability to prevent heat transfer fluid freezing. It can entail using drainback systems or antifreeze solutions.

ii. Heat Output: Is the quantity of heat energy transferred to the working fluid or storage system usually expressed in kilowatts (kW). It is affected by collector area, radiation levels, and efficiency.

iii. Operating Temperature Range: The operating temperature range outlines the maximum and minimum temperatures that the collector’s heat transfer fluid will tolerate. It accounts for the lowest and highest temperatures the collector can tolerate without becoming ineffective or getting damaged.

iv. Optical Efficiency: Gauges how well the flat plate solar collector captures solar light. It provides an indication pf how much solar radiation is successfully harvested.

v. Pressure Drop: An excessive pressure drop can negatively affect thermal efficiency by reducing the fluid flow rate.

vi. Temperature Rise: The heat transfer fluid’s temperature rise while traversing the collector reveals the collector’s temperature rise. It’s the difference between the fluid temperatures at the inlet and outlet affected by collector efficiency, radiation levels and flow rates.

vii. Thermal Efficiency: It determines how well the solar collector converts sun’s energy to useful thermal energy. It is the ratio of the useful heat output to the incident solar radiation expressed in percentage from.

viii. Certification and Standards: Flat plate solar collectors are subject to industry standards to guarantee their dependability and effectiveness. Some common accreditations include those by the Solar Rating and Certification Corporation (SRCC), which grades solar thermal equipment and offers independent testing.

Maintenance of Flat Plate Solar Collectors

The effectiveness and dependability of a flat plate solar collector system is ensured by adhering to maintenance procedures. Some essential maintenance procedures include:

- Regular Cleaning: Helps in eliminating dirt and other foreign matter that may accumulate on the collector over time. Utilize soft material like brush or sponge avoiding the use of aggressive chemicals or abrasive products that can ruin the collector.

- Inspect for Leakage: Look for any leaks by checking the collector and associated plumbing infrastructure. Signs of leakage include dripping, water stains or moisture. Undertake immediate repair to avert greater damage and sustain integrity of the system.

- Verify Fluid Levels: Check the level of fluid in the collector and any connected circulation or storage systems ensuring they’re within the suggested range. Inefficient heat transfer and potential system problems can result from low fluid levels.

- Inspect Glazing and Seals: Check the glazing material for damage inform of cracks or color change. Also verify the quality and tightness of the seals around the glazing’s edges. For optimum insulation and curbing air or moisture leakage, replace defective glazing or seals.

- Monitor System Performance: Keep a close eye on the solar collector system’s operation verifying flow rates and fluid temperature differences. Examine and immediately address large departures from the norm.

- Insulate Pipes and Ducts: Ensure that the collector and heat transfer system’s pipes and ducts are adequately insulated. Insulation keeps fluid temperatures ideal during circulation reducing heat losses. Any damaged insulation must be changed or repaired.

- Monitor and Trim Vegetation: Be on the lookout for overgrowth of vegetation like trees that can shadow the collection and trim as is necessary. If left uncontrolled, vegetation can block the sun’s rays and lower the amount of solar energy reaching the collector.

- Follow Manufacturer Instructions: Comply with the flat plate solar collector’s manufacturer’s instructions for maintenance. Pay attention to their advice regarding maintenance schedules, certain cleaning techniques, and any other maintenance needs unique to the collector model.

- Licensed Inspection: Consider having the collector system inspected by a qualified solar thermal expert on a regular basis. They may carry out more thorough checks, spot hidden issues, and offer knowledgeable advice on system upkeep and optimization.

Conclusion

Flat plate solar collectors are a go to choice for both domestic and commercial heating applications as well as some industrial processes. They’re renowned for being straightforward, dependable, and economical while lowering dependence on traditional fossil fuel-based heating systems and greenhouse gas emissions.